Amphorae and other different, more or less exotic, maturation vessels are seemingly invading Burgundy. One can now find elevage in traditional terracotta amphorae, ceramic vessels, glass vats, stainless steel vats, and then of course the numerous variations on oak and its toasting.

This is complex; very complex indeed.

The latest tendencies

The Italian-made Clayver Ceramic vessel are seemingly one of the hottest new elevage vessels, in use by producers such as Arnoux-Lachaux, who has changed a large part of his elevage to these containers.

The Clayver is relatively new, and the first I heard about these vessels in Burgundy was from Jérémy Recchione and Charles Lachaux during their tests.

Now it seems that some people are ready to enter a new phase in which the Clayver goes into full production.

What is the Clayver

The Clayver website, quoted below, explains a lot:

Clayver: Innovation, precision, and scientific verification of materials

Clayver is a ceramic container designed specifically for winemaking, including in this definition fermentation, preservation, and refinement of the product. It is the result of long work of research and experimentation. All containers are produced by us, under our direct supervision, from raw materials that we carefully select from the best suppliers, to ensure uniformity and consistency in the final product.

Clayver ceramic wine barrels are made of particularly homogeneous and compact natural ceramic stoneware. This material is similar in many aspects to a natural granite: it is impermeable to liquids and therefore it does not need any precaution in order to avoid evaporation. The intrinsic microporous structure of the ceramic material can allow a gaseous exchange with the outside of the container, but only in limited quantities and on very long time scales. The container is therefore also suitable for long aging.

The ceramic is certified for food use, with controlled porosity, patented hermetic closure, high thermal inertia, and easy cleaning.

Clayver’s added values:

– The use of an excellent material;

– A reliable production system that guarantees repetitive quality;

– Traceability through the archive of coded samples;

– Periodic laboratory analysis;

– Machinery built by the company itself that guarantees, through technique and manual skill, special surface finishes and quality control of the product.

Typical technical data for Clayver stoneware

– Oxygen distance in O₂ 121 pm

– Oxygen-hydrogen water molecule distance 95.84 pm

– Water molecule hydrogen distance152.50 pm

Clayver vs. oak and traditional clay amphorae

I am definitely no expert in either ceramic vessels or oak barrels when it comes to specific technical data on the different enclosures. What I do know is that Clayver is natural in the sense that it is manufactured from natural materials.

From the FAQ on the Clavyer website:

Is Clayver “natural”?

The adjective “natural” is often abused. Clayver is a man-made product, but all the raw materials in the mix have natural origins. They are selected for their purity and oenological suitability, mixed with water, molded into a spherical shape, and finally fired. Nothing else.

What differences are there relative to wood?

Again from the web site:

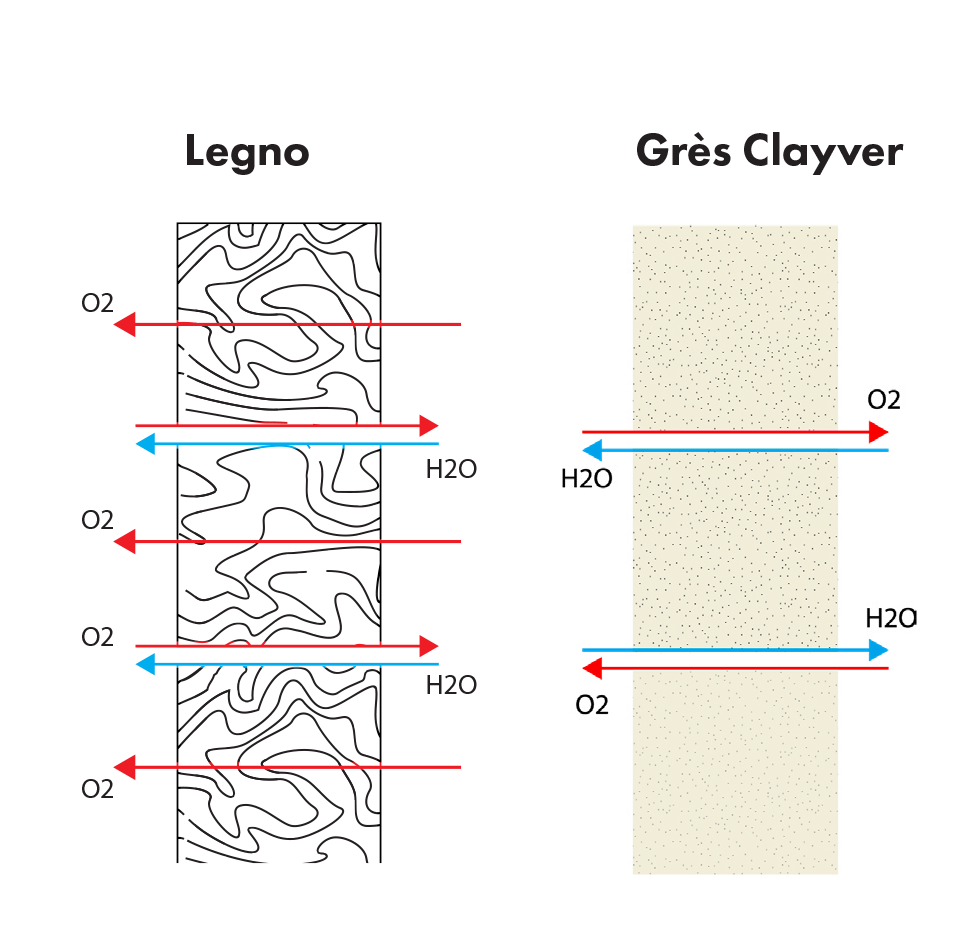

The main difference between Clayver and wood consists in the absence of substances released into the wine. Clayver’s porosity is equivalent to that of wood, but the oxygen transfer rate is generally lower, because of wood’s different organic matrix.

This means that the oxygen transfer – the oxidation – is smaller when using Clayver than a traditional oak barrel.

You need to login as a Premium subscriber to read the rest of this article. If you are not a Premium Subscriber, use the subscribe function and sign-up.

- A true vin d’émotion – a Burgundy of passion

- A true vin d’émotion – a Burgundy of passion - A truly hedonistic wine – lively and enjoyable

- A truly hedonistic wine – lively and enjoyable - A vivacious wine for pure indulgance

- A vivacious wine for pure indulgance - A potential vin d´émotion - frais et léger

- A potential vin d´émotion - frais et léger